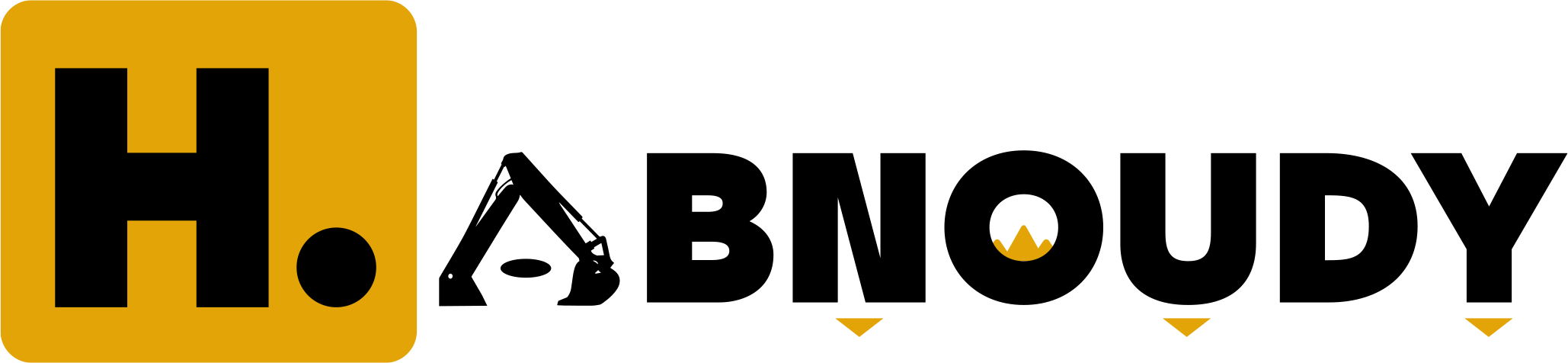

Silica sand is a naturally occurring granular material composed of finely divided rock and mineral particles. It is one of the most abundant minerals on Earth and has a wide range of applications across various industries. From construction to glassmaking, filtration to fracking, silica sand plays a crucial role in many processes and products that we rely on daily. Let’s delve deeper into what silica sand is, its properties, uses, and environmental considerations.

What is Silica Sand

What is Silica Sand?

Silica sand is primarily composed of silicon dioxide (SiO2) and is found in abundance in the Earth’s crust. It forms from the erosion and weathering of quartz-rich rocks over millions of years. The process of creating silica sand involves crushing, washing, and refining the raw material to remove impurities such as clay, silt, and organic matter, resulting in a clean, uniform product with high silica content.

Properties of Silica Sand

- High Purity: Silica sand is prized for its high purity, typically containing more than 95% silica content, which makes it ideal for various industrial applications.

- Grain Size: The size of silica sand grains can vary from very fine particles to coarse granules, depending on the intended use.

- Chemical Inertness: Silica sand is chemically inert, meaning it does not react with other substances, making it suitable for applications where stability and non-reactivity are essential.

- High Melting Point: Silica sand has a high melting point, making it a key component in glassmaking and foundry casting processes.

- Abrasive Properties: Due to its hardness and angular shape, silica sand is used as an abrasive in sandblasting and surface finishing applications.

What is Silica Sand

Uses of Silica Sand

- Glassmaking: One of the primary uses of silica sand is in the production of glass. The high silica content and purity help create clear, durable glass for windows, bottles, optical fibers, and other glass products.

- Foundry Casting: Silica sand is used in foundries as a mold material due to its ability to withstand high temperatures and create intricate shapes when compacted.

- Construction: Silica sand is a key ingredient in concrete and mortar, providing strength and durability to building materials.

- Filtration: It is used in water filtration systems, swimming pool filters, and wastewater treatment processes to remove impurities and contaminants.

- Fracking: In the oil and gas industry, silica sand is used in hydraulic fracturing (fracking) operations to prop open fractures in rock formations and facilitate the extraction of hydrocarbons.

What is Silica Sand

Environmental Considerations

While silica sand offers numerous benefits in various industries, its extraction and processing can raise environmental concerns. Mining and processing operations can disturb ecosystems, impact water quality, and contribute to air pollution if not managed properly. Additionally, the fine particles of silica dust generated during handling and processing can pose respiratory health risks to workers and nearby communities.

To mitigate these environmental and health risks, responsible mining practices, dust control measures, and proper waste management are essential. Recycling and reusing silica sand whenever possible can also reduce the demand for new extraction.

In conclusion, silica sand is a versatile and valuable natural resource with a wide range of applications in industry. Understanding its properties, uses, and environmental impact is crucial for sustainable utilization and conservation efforts. As industries continue to evolve, finding innovative ways to harness the benefits of silica sand while minimizing environmental footprint remains a key challenge and opportunity.

0 Comments